Grinding Equipment Pharmaceutical Engineering

171K subscribers 495 Share 22K views 2 years ago Dear Friends & Students in this video we had discussed in detail about 2 size reduction equipment 1. Edge Runner Mill 2. End Runner Mill.

Edge Runner Mill Principle, Construction, Working & Uses Of Edge Runner Mill YouTube

Telegram link:https://telegram.me/pharmalecture1 Website link for notes :http://www.pharmalecture.com Instagram link: https://www.instagram.com/invites/cont.

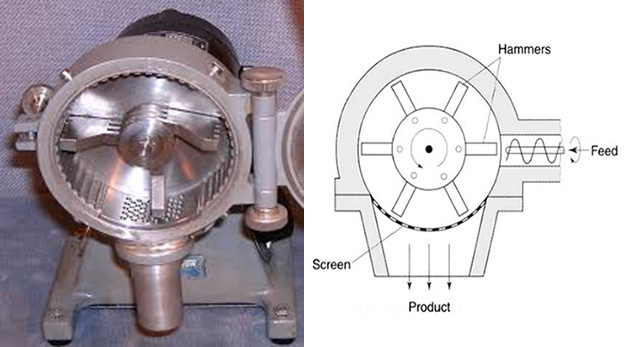

Illustration of a hammer mill. Download Scientific Diagram

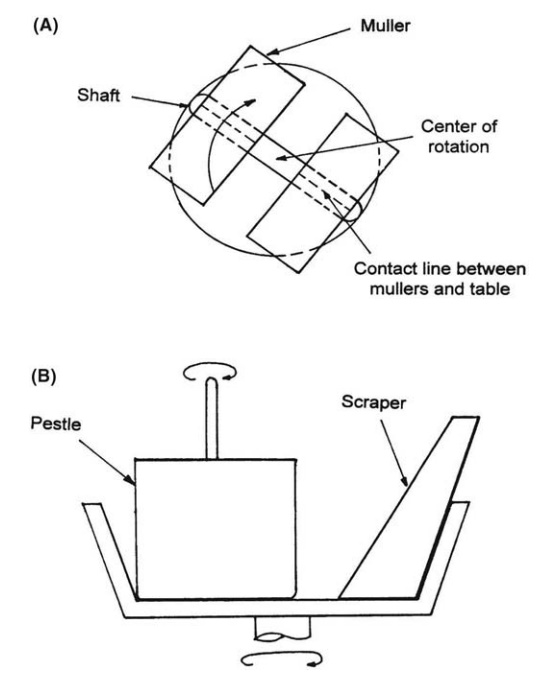

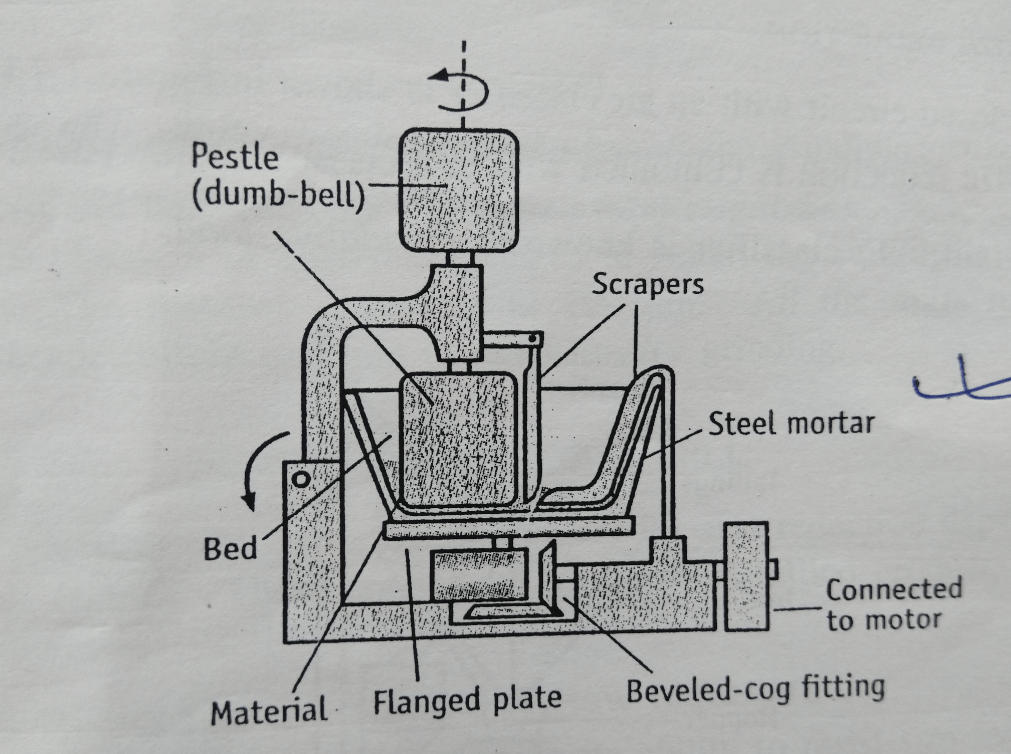

End-runner mills are the mechanized forms of mortar and pestle-type compression comminution. This milling equipment consists of a pestle made of either stone or metal, connected by a shaft, Fig.1. The pastel rotates at its axis in a shallow steel or porcelain mortar. The pestle is mostly dumb-bell shaped.

7 Edge and End Runner mills Animation Size reduction B.pharma Pharmaceutical Engineering Tamil

1. It is not suitable for milling sticky materials 2. Machine noise leading to noise pollution References Sud Sushant and Kamath Archana (2013). Methods of Size Reduction and Factors Affecting Size Reduction in Pharmaceutics. International Research Journal of Pharmacy. 4 (8): 57-64.

Patent US573890 Edgerunner mill Google Patents

also dust extracted during their firing in furnaces can be briquetted on edge runner mills and used for making refractories. However, the selection of the pressing parameters and the standard sizes. Diagram of the stresses developed during briquetting on edge runner mills. Translated from Ogneupory, No. 8, pp.25-29, August, 1967. 479 !.

Edge runner mill YouTube

Edge Runner Mill and End Runner Mill with working videos Swati Londhe 282 subscribers 1.3K views 3 years ago This video covers principle, construction, working, uses, merits and demerits.

Endrunner mill and Edgerunner mill Operating principles, Uses

Edge and End Runner Mills. The edge runner mill consists of one or two heavy granite or cast iron wheels or mullers mounted on a horizontal shaft and standing in a heavy pan. Either the muller or the pan is driven.. FIGURE 12.6 Diagrams of (A) vibro-energy mill and (B) fluid energy mill. This, it is claimed, gives preferential grinding of.

Working Principle of Edge Runner Mill Solution Parmacy

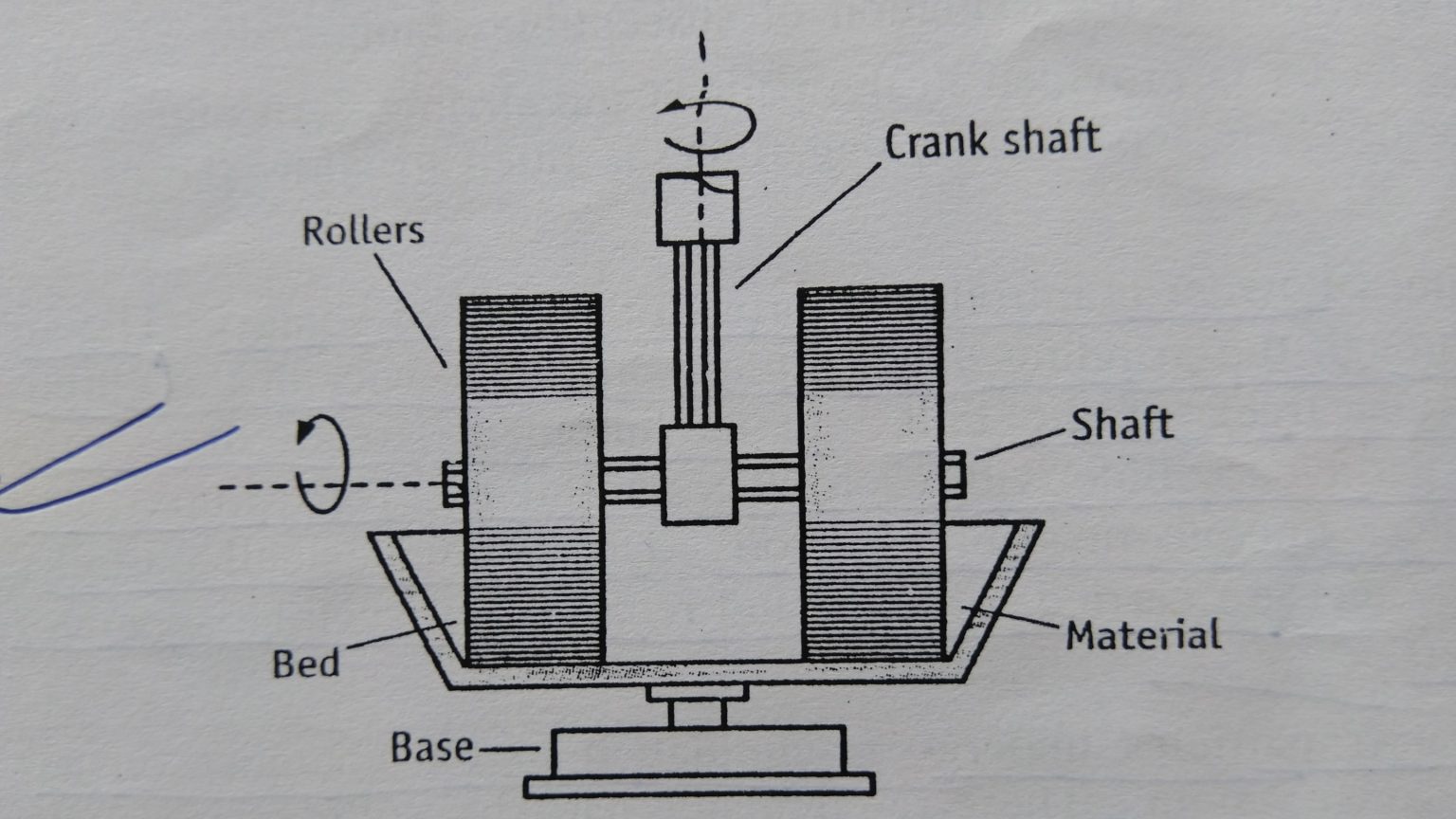

Edge runner mill, also known as Chilean mill or Roller stone mill consists of one or two heavy steel or granite rollers mounted on a horizontal shaft and turned round a central vertical.

Hammer Mill Boson Machinery

The edge runner mill is also called a roller stone mill and is a mechanized form of mortar and pestle-type compression comminution. It crushes the materials into fine powders by rotating stones. The edge runner mill consists of two large rotating grinding wheels or stones turning slowly in a large bowl.

Edge Runner & End Runner Mill I Size Reduction I Pharma Engineering I BP 304T I L12 YouTube

Edge Runner Mill / Roller Stone Mill. Principle. The size reduction is done by crushing due to heavy weight of the stones and the shearing force which is involved during the movement of these stones. Construction. It consist of two heavy rollers and a bed made of stones or granite. The roller have a central shaft and they revolve on its axis.

Construction, Working of End Runner Mill Solution Parmacy

A millstone could be either a runner (top) or bed (bottom) stone; used in pairs to rotate on a common axis, and to cut the grain into meal-which was then sifted to produce (in progressive finenesses) flour, middlings and bran. Each millstone would be typically about 4 feet in diameter, cylindrical, about a foot thick, and very heavy.

Size Reduction Fluid Energy Mill Edge Runner Mill End Runner Mill part4 P

The edge-runner mill was another commonly used crushing device. With the latter a circular stone on edge running around a lower millstone was used to pulverize. The edge runner appeared in China in the 5 th century AD. Both the trip hammer and edge runner were not used in Europe until eight centuries later.

Edge runner mill YouTube

The edge runner mill is also called a roller stone mill and is a mechanized form of mortar and pestle-type compression comminution. It crushes the materials into fine powders by rotating stones. The mill consists of two large rotating grinding wheels or stones turning slowly in a large bowl.

Hammer mills Paolini, Antonio Palmiro Metal Hammers, Mill

Edge-runner mills with a capacity of I000 liters are used in the shops of the Boroviehi Combine for the preparation of semi-dry ehamotte mixtures.. diagram shows the old type and the new modified design. The adoption of the new design has made it possible to replace the tires on spot without removing roller;.

Metal Casting and Turnkey Specialist, SM Metal Solutions

Usage: Runner Mill is used to grinding hard materials to get fine particles. The mill is also used for plant-based products. Merits Easy to use. It is free to move without any attention. East to clean and required less space to install. Demerits As it is not much compact so chances of contamination are high. No use for sticky materials

Vintage Illustration of a Vertical Section of an Edgerunner Mill for the Incorporation of

Fluidized Energy mill, also known as micronizer or jet mill is a type of mill that consists of a hollow toroid that has a diameter of 20-200 mm depending on the height of the loop which can be up to 2 m. It operates by particle impaction and attrition. A fluid or milling gas, usually air or inert gas is injected as a high-pressure jet through.